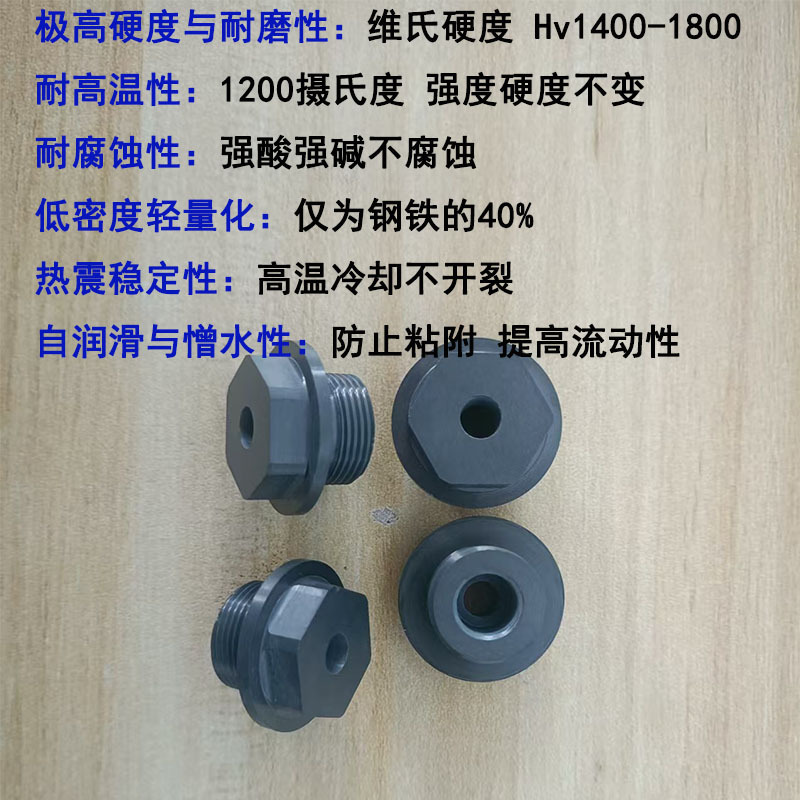

Silicon nitride ceramic nozzles are wear-resistant, high-temperature resistant, corrosion-resistant and thermal shock-resistant. Non-standard customized parts for continuous casting sandblasting and shot blasting machines

Silicon Nitride Ceramic Nozzle - High-Performance Solution for Industrial Applications

When it comes to demanding industrial environments, the Silicon Nitride Ceramic Nozzle stands out as a superior choice for abrasion resistance, high-temperature stability, and corrosion resistance. Manufactured in China's Hebei province, this nozzle is designed for custom applications across multiple industries.

Key Features

- Material: High-purity silicon nitride (Si3N4)

- Temperature Resistance: Up to 1200°C

- Pressure Range: 1400-1800 (customizable)

- Customizable Design: Available in various sizes (2-100mm) and connection types (threaded, flanged, quick-connect)

- Manufacturing Process: Gas pressure sintering for optimal density and strength

Applications

This versatile nozzle is engineered for challenging environments in:

- Metallurgical continuous casting

- Metal surface treatment (sandblasting, shot peening)

- Chemical and environmental protection systems

- Energy sector (coal gasification, oil/gas boilers)

- Advanced manufacturing & 3D printing

- High-pressure cleaning systems

- Food processing industry

Why Choose Our Silicon Nitride Nozzles?

The HICERA brand represents excellence in ceramic engineering. Our nozzles offer:

- Exceptional thermal shock resistance

- Superior wear resistance compared to traditional materials

- Chemical inertness against most corrosive media

- Precision manufacturing with tight tolerances

- Custom solutions based on your technical drawings or samples

Customization Options

We provide OEM services with flexible specifications:

- Bore diameter: 2-100mm (adjustable)

- Connection types: External/internal threads, flanges, quick connectors

- Special shapes and configurations

- Surface treatments upon request

For industries requiring durable, high-performance nozzles that withstand extreme conditions, our silicon nitride ceramic nozzles deliver unmatched reliability and longevity. Contact us today to discuss your specific application requirements.