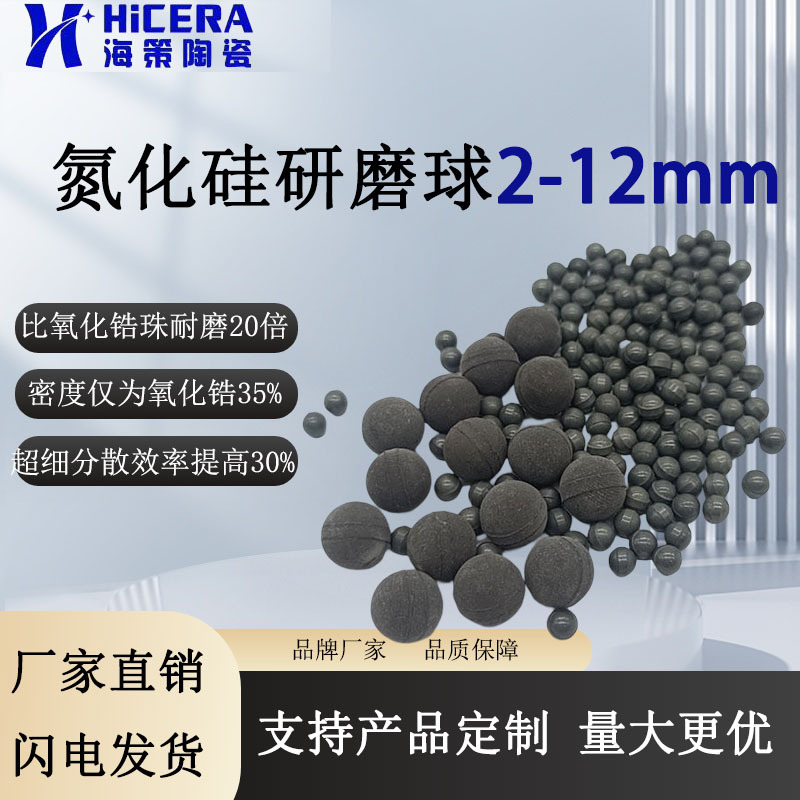

Super wear-resistant silicon nitride ceramic grinding balls, heat storage and heat conduction grinding medium balls, filter balls, packing balls can remove the ring band

Ultra-Wear-Resistant Silicon Nitride Ceramic Grinding Balls

Discover the exceptional performance of HICERA's Silicon Nitride (Si3N4) Ceramic Grinding Balls, engineered for superior wear resistance, thermal conductivity, and precision grinding applications.

Key Features:

- Material: High-purity Silicon Nitride (Si3N4, ≥96%)

- Density: 3.26±0.02 g/cm³

- Model: 2mm-12mm (with 2mm ringed variant available)

- Sphericity: 0.97% (near-perfect roundness)

- Crushing Load: 40Kgf (exceptional mechanical strength)

Why Choose HICERA's Grinding Balls?

Our silicon nitride balls outperform traditional materials with:

- 5x longer service life than zirconia balls

- 50% lower contamination risk vs. metal media

- Excellent thermal shock resistance (ΔT up to 800°C)

- Chemically inert for corrosive environments

Applications:

Ideal for high-end material processing including:

- Ultra-fine dispersion grinding of ceramics

- Electronic component polishing

- Pharmaceutical nano-grinding

- High-purity pigment processing

Technical Advantages:

| Property | Value |

|---|---|

| Vickers Hardness | ≥1500 HV |

| Thermal Conductivity | 25-30 W/(m·K) |

| Coefficient of Friction | 0.1-0.15 (self-lubricating) |

Quality Assurance:

Every batch undergoes rigorous testing including:

- 100% dimensional inspection

- Random crushing load tests

- Surface roughness verification (Ra ≤ 0.05μm)

Made in China - Proudly manufactured in Handan, Hebei with ISO-certified production facilities.

Note: Non-hazardous material, complies with RoHS/REACH standards.