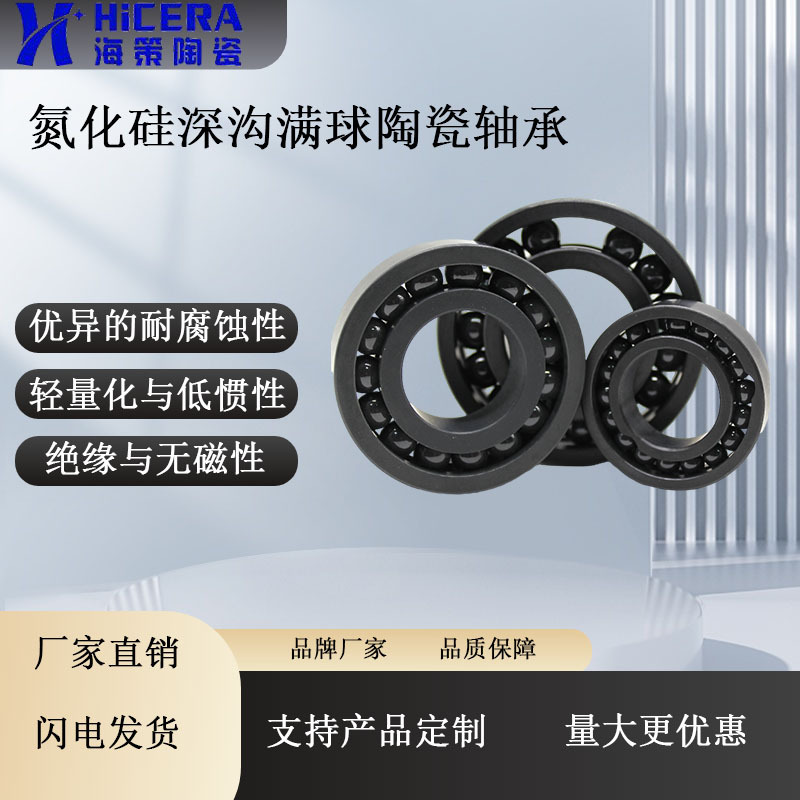

Silicon nitride ceramic full ball deep groove ball bearings are available in stock directly from the manufacturer

Revolutionize Your Applications with HICERA 6200: The PEEK Deep Groove Ball Bearing with Corrosion-Resistant Ceramic Balls

In the demanding world of precision engineering, selecting the right bearing is not just a choice—it's a strategic decision that impacts performance, longevity, and operational costs. For applications where traditional steel bearings fall short, a superior alternative has arrived. Enter the HICERA 6200, a single-row, unsealed deep groove ball bearing engineered from advanced PEEK plastic and fitted with corrosion-resistant ceramic balls. This combination creates a component that is truly in a class of its own.

Why does this matter? Imagine environments plagued by constant moisture, aggressive chemicals, or stringent requirements for electrical non-conductivity and low friction. Standard bearings corrode, seize, or fail prematurely, leading to costly downtime and maintenance. The HICERA 6200 is specifically designed to conquer these challenges head-on.

The Power of Material Science: PEEK & Ceramic Synergy

The core innovation of the 6200 series lies in its material composition. The bearing ring and cage are constructed from PEEK (Polyether Ether Ketone), a high-performance thermoplastic polymer renowned for its exceptional properties.

- Outstanding Chemical Resistance: PEEK is virtually inert, offering superb resistance to a wide range of harsh chemicals, solvents, and steam. It outperforms metals and many other plastics in corrosive environments.

- High-Temperature Performance: It maintains excellent mechanical strength and dimensional stability at continuous service temperatures up to 250°C (482°F).

- Inherent Lubricity & Low Wear: PEEK has a naturally low coefficient of friction, reducing the need for external lubricants and minimizing wear on both the bearing and its mating surfaces.

- Electrical Insulation & Non-Magnetic: Perfect for electrical applications and environments sensitive to magnetic interference.

Complementing the PEEK structure are the corrosion-resistant ceramic balls. Typically made from silicon nitride (Si3N4) or zirconia, these balls add another layer of performance:

- Zero Corrosion: Ceramic is impervious to rust and oxidation, making it ideal for wet or chemically aggressive settings where steel balls would degrade.

- High Hardness & Stiffness: They provide exceptional durability, reduced deformation under load, and longer service life.

- Lightweight: Ceramic balls are significantly lighter than steel, reducing centrifugal forces and enabling higher rotational speeds.

Key Applications for the HICERA 6200 Bearing

This bearing is not a general-purpose component; it's a specialized solution for critical applications. Its unique properties make it indispensable in:

- Chemical Processing Equipment: Pumps, mixers, and agitators exposed to acids, alkalis, and solvents.

- Food & Beverage and Pharmaceutical Machinery: Where corrosion resistance, cleanliness, and FDA-compliance of materials are paramount. The unsealed design (available) allows for easy cleaning.

- Marine & Offshore Applications: Equipment constantly exposed to saltwater spray and high humidity.

- Electrical & Semiconductor Manufacturing: Non-conductive, non-magnetic bearings for precision tools and cleanrooms.

- High-Purity Water Systems: In desalination plants or ultrapure water circulation where metallic contamination must be avoided.

Why Choose HICERA 6200? Features and Immediate Availability

Choosing the HICERA 6200 model provides clear, tangible benefits for engineers and procurement specialists:

- Ready-to-Ship (现货): No long lead times. The bearing is available from stock, allowing you to address maintenance needs or kick-start new projects immediately.

- Proven Design: The standard 6200 deep groove geometry ensures reliable radial load handling and easy integration into existing designs.

- Maintenance Simplification: The combination of corrosion resistance and low friction often reduces or eliminates the need for complex lubrication systems, lowering total cost of ownership.

- Brand Assurance: HICERA is a recognized name in precision bearing manufacturing, ensuring consistent quality and performance.

In conclusion, the HICERA 6200 PEEK Deep Groove Ball Bearing with corrosion-resistant ceramic balls represents a leap forward in bearing technology for hostile environments. It transforms operational challenges into reliable, long-lasting performance. Don't let corrosion and material incompatibility limit your equipment's potential.

Upgrade to the durable, high-performance solution. Source the HICERA 6200 bearing today and build resilience into your machinery.