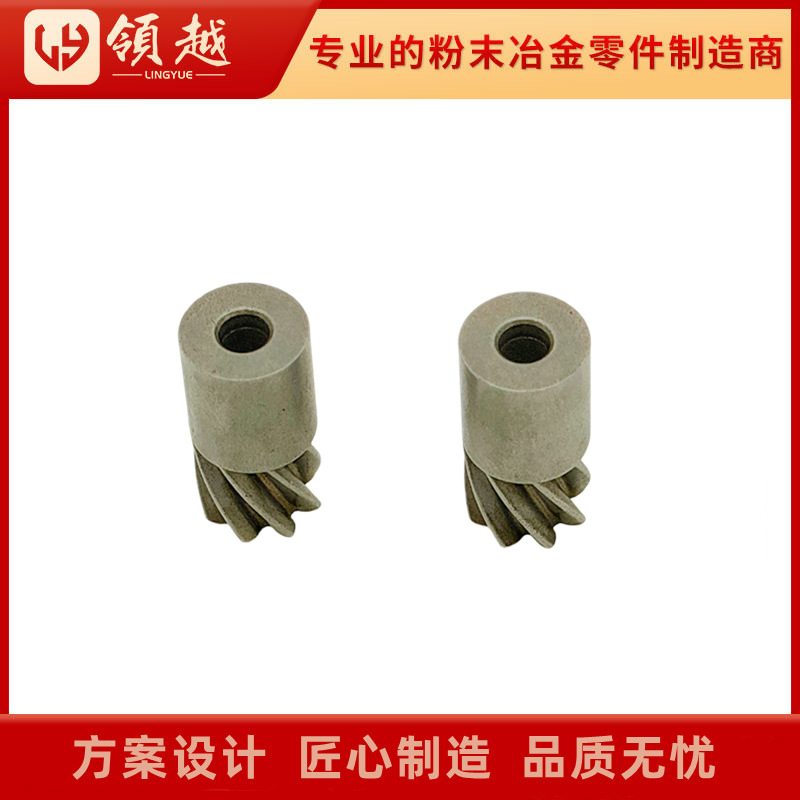

Powder metallurgy gear manufacturers customize helical gears, helical gears, bevel gears, mini gear parts and alloy processing

Customized Powder Metallurgy Gears for Lock Systems

In the world of precision engineering, finding the right components for your lock systems can be a challenge. That's where our customized powder metallurgy gears come into play. Designed to meet the highest standards of durability and performance, these gears are the perfect solution for your lock mechanism needs.

Why Choose Our Powder Metallurgy Gears?

Our gears are manufactured using traditional powder metallurgy processes, ensuring high precision and excellent mechanical properties. Here’s what makes our product stand out:

- Material: Made from high-quality nickel alloy for superior strength and corrosion resistance.

- Powder Preparation: Utilizes advanced atomization method for uniform particle distribution.

- Molding: Precision die pressing with hard alloy molds ensures dimensional accuracy.

- Sintering: Solid-phase sintering in a decomposed ammonia atmosphere at temperatures ranging from 1050°C to 2000°C.

- Post-Processing: Includes heat treatment for enhanced durability.

Applications in Lock Systems

Our powder metallurgy gears are specifically designed for lock systems, providing smooth operation and long-lasting performance. Whether you need standard or custom designs, we can deliver solutions tailored to your exact requirements.

Customization and Lead Time

We understand that every project is unique. That’s why we offer fully customizable solutions:

- Prototyping: Sample lead time of 8-15 days.

- Production: Full-scale production completed within 8-15 days.

- Flexible Specifications: Tailored to your design and functional needs.

Conclusion

When it comes to high-performance gears for lock systems, our powder metallurgy solutions deliver unmatched precision and reliability. With advanced manufacturing techniques and customizable options, we’re your trusted partner for all your gear requirements.

Contact us today to discuss your project and get a quote!